In the high-stakes aerospace industry, where precision, reliability, and safety are non-negotiable, the production of critical components like fuel lines demands cutting-edge manufacturing solutions. Among the technologies that have become indispensable to aerospace manufacturers worldwide, hydraulic Tube end forming machines stand out as a cornerstone of efficient, high-quality fuel line production—offering capabilities that align with the sector’s rigorous standards and evolving needs.

Aerospace fuel lines are tasked with transporting fuel under extreme conditions: fluctuating pressures, wide temperature ranges, and the structural stresses of flight. Even the smallest imperfection in a fuel line’s design or fabrication can have catastrophic consequences, making precision the top priority for manufacturers. Hydraulic tube end forming machines excel in this regard, leveraging hydraulic power to shape tube ends with micron-level accuracy. Unlike mechanical forming methods, hydraulic systems deliver consistent force across the tube’s surface, ensuring uniform wall thickness, tight dimensional tolerances, and seamless connections to fittings, valves, and other components. This level of precision eliminates leak points, reduces the risk of fuel system failures, and ensures compliance with strict aerospace regulations, including those set by global aviation authorities.

Beyond precision, hydraulic tube end forming machines offer unmatched versatility— a key advantage in an industry where fuel line designs vary widely based on aircraft type, engine configuration, and performance requirements. These machines can handle a range of tube materials commonly used in aerospace applications, from lightweight aluminum alloys and corrosion-resistant titanium to high-strength stainless steel. Whether forming flanges, beads, swages, or custom profiles, hydraulic systems adapt to diverse tube diameters and wall thicknesses, enabling manufacturers to produce complex, application-specific fuel line designs without sacrificing efficiency. This versatility reduces the need for multiple specialized machines, streamlining production workflows and lowering operational costs.

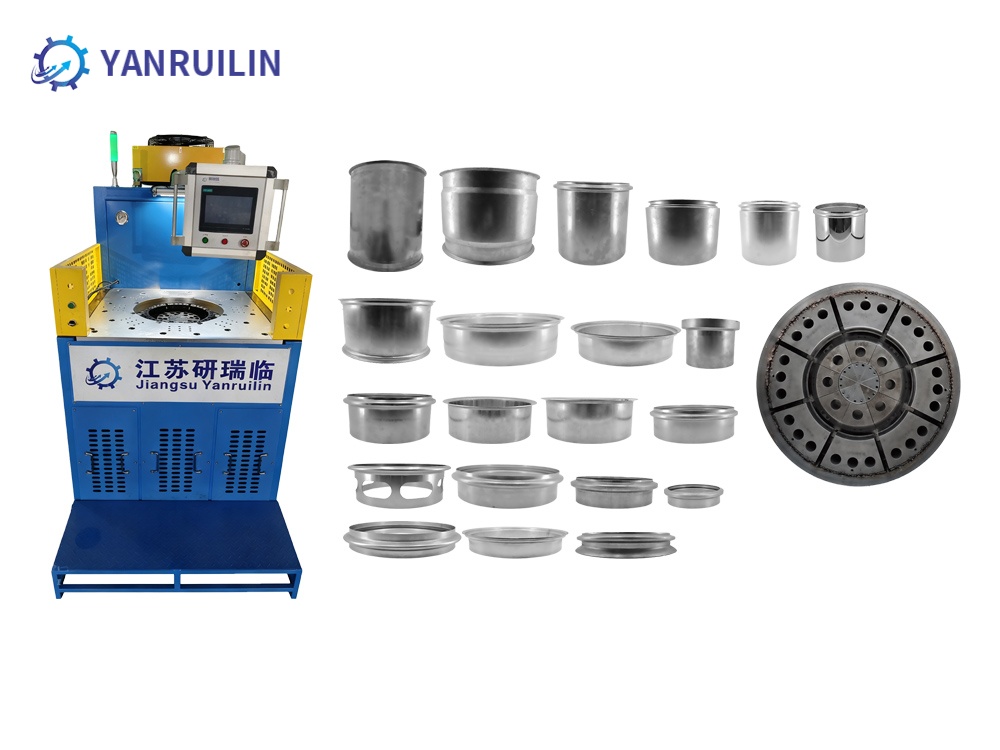

Tube end forming machines

Efficiency and scalability are also critical factors driving aerospace manufacturers to adopt hydraulic tube end forming technology. In an industry characterized by high-volume production runs and tight delivery timelines, these machines deliver fast cycle times, thanks to their powerful hydraulic drives and automated controls. Many modern systems integrate with computer numerical control (CNC) technology, allowing for programmable forming sequences, repeatable results, and minimal human intervention. This automation not only boosts production throughput but also reduces the potential for human error— a critical consideration in aerospace manufacturing, where consistency is as important as speed. Additionally, hydraulic machines are designed for durability and low maintenance, with robust construction that withstands the demands of continuous industrial use, minimizing downtime and ensuring long-term productivity.

Safety, a paramount concern in aerospace, is another area where hydraulic tube end forming machines deliver significant value. Fuel line components must meet strict fire resistance, pressure resistance, and fatigue strength standards to withstand the harsh operating environment of aircraft. Hydraulic forming processes create stronger, more resilient tube ends compared to traditional methods, as the uniform force application preserves the material’s structural integrity and reduces the risk of cracks or deformation over time. Furthermore, the sealed, controlled nature of hydraulic systems minimizes the risk of contamination during forming— a critical advantage, as even small particles or debris in fuel lines can damage engines or cause system malfunctions.

As the aerospace industry evolves— with a growing focus on fuel efficiency, lightweighting, and next-generation aircraft designs— the demand for advanced manufacturing technologies continues to rise. Hydraulic tube end forming machines are well-positioned to meet this demand, offering the precision, versatility, and reliability needed to produce fuel lines that support safer, more efficient flight. By investing in these systems, aerospace manufacturers can not only ensure compliance with the industry’s most stringent standards but also gain a competitive edge in a market where quality and performance are the ultimate differentiators.

In summary, hydraulic tube end forming machines have become an essential tool for aerospace manufacturers producing critical fuel lines. Their ability to deliver micron-level precision, adapt to diverse materials and designs, enhance production efficiency, and uphold the highest safety standards makes them irreplaceable in an industry where there is no room for compromise. As aerospace technology advances, these machines will continue to play a pivotal role in shaping the future of fuel line production— enabling safer, more reliable, and more efficient aircraft for years to come.

이 웹사이트는 귀하가 당사 웹사이트에서 최상의 경험을 할 수 있도록 쿠키를 사용합니다.

논평

(0)